OUR FACILITY

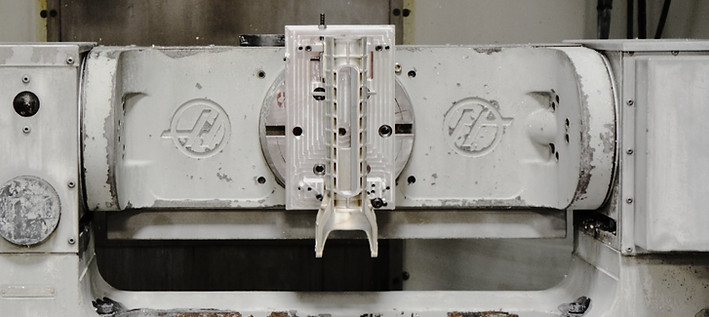

MACHINING CENTERS

With nearly 20 Haas CNC Machining Centers, we have the capabilities to complete the most complex 3, 4, and 5-axis milling operations.

We use Mastercam Mill Level 3 software to ensure efficient toolpaths while maintaining the highest levels of precision in both machined castings and parts machined from solid bar or plate.

MILLING

For smaller jobs, we're equipped with 8 ProtoTrak CNC Milling Machines. These machines are essential for quick turnaround lower volume detail work and fixturing.

Our highly skilled machinists and tool & die makers have hundreds of years of combined experience. From facing, to slots, drilling, tapping, and chamfers, we've got every operation covered.

TURNING

In addition to milling, we also excel in high precision CNC turning. We have the ability to get jobs up and running quickly and are able to hold very tight tolerances on a wide range of materials.

For parts requiring heat treating, grind stock is left so that critical features such as bearing diameters can be precision ground to final size assuring proper fit and function.

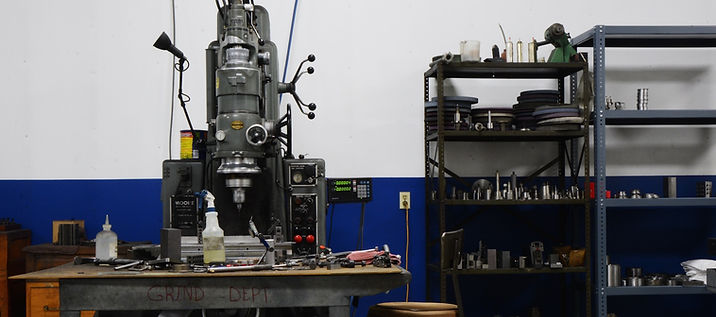

GRINDING

Our grinding department is equipped with surface, OD, ID and jig grinders. These are vital for holding dimensional accuracy and maintaining high levels of precision.

WIRE EDM

We specialize in Wire EDM Machining, or Wire Electrical Discharge Machining. We excel in cutting both gear, and spline tooth profiles to precision tolerances as well as many other complex profiles.

Wire EDM is often used as an alternative to cutting longer profiles that would be difficult using conventional methods due to tool deflection, small internal radii, or to eliminate the need for broaching.

SINKER EDM

In addition to our Wire EDM machines, we also have 3 conventional or sinker EDM machines. These allow us to machine complex internal shapes that do not go through the part or that cannot be done using the Wire EDM process.

An example of this would be our ability to machine precision internal gear or spline tooth profiles that have an internal shoulder.

Our sinker EDM machines use automatic tool changers which allow us to achieve maximum throughput.

QUALITY CONTROL

Quality is number one at Micron Precision Machining, Inc. Our team is committed to continuous improvement, and we are ISO 9001:2015 certified.

We have a state of the art Quality Department and are able to provide detailed CMM reports.

We can import customer supplied CAD models into our Zeiss CMMs for quicker throughput. This can drastically reduce the turn around time when programming and inspecting complex parts.

MATERIALS

At Micron, we strive to push the limits on machining new and complex materials.

We can machine a wide range of ferrous and non-ferrous metals, plastics, and composites.

We also provide end-to-end material treatment services, like hardening and anodizing. We will ensure that your parts are handled with care and manufactured to your specification.

PROTOTYPING - MACHINED CASTINGS - PRODUCTION - INSPECTION

PROTOTYPING

Prototyping lies at the heart of Micron. We have been machining precision prototype details for over 15 years.

Our shop is optimized for quick turn around times and small batch sizes. With our in-house, expert team of machinists, you'll be surprised at how quickly we can make your drawings or models come to life.

MACHINED CASTINGS

From driveline component covers to steering yokes, Micron has been machining cast parts for the automotive industry for nearly 10 years.

We have the knowledge and expertise to take on prototype and small production jobs.

Our in-house quality department helps reduce lead-times while ensuring dimensional accuracy.

PRODUCTION

Prototype work at scale. After cutting our teeth in the prototype business, we have started to take on small production jobs.

We're able to maintain high levels of throughput by using the latest technology and optimizing toolpaths to reduce wear and machine downtime.

Our 42,000sqft facility provides ample space to setup manual or automated manufacturing cells.

INSPECTION

Our inspection and quality department has been growing rapidly for the past 5 years.

Whether you're looking for third party inspection or process repeatability, we have the tools to help.

We use cutting edge technology to create inspection reports for reference and validation.

SERVICES

WHO WE ARE

Micron Precision Machining, Inc. is a full service, custom machine shop. We're comprised of machinists, programmers, and quality specialists that will help bring your designs to life.

ABOUT US

WHAT WE DO

At Micron, we specialize in the manufacture of precision and prototype parts. We take pride in our work and our ability to produce the most complex parts using a wide range of metals, plastics, and other materials.

WHERE

We're proudly based in the USA.

Micron Precision Machining, Inc.

225 E. Morely Dr.

Saginaw, MI 48601

USA